RV-9A: Flap Motor & Landing Gear Mounts - 1/10/2010

Home Previous Entry Next Entry Back |

Share on:

|

|

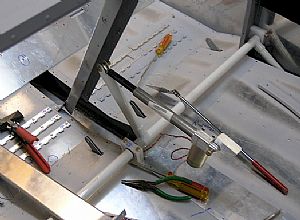

Bolted the flap motor to the actuator Bolted the flap motor to the actuator

It was tough to get all the washers and the glap motor in place. I had to open the actuator gap a little to get all the parts in place.

|

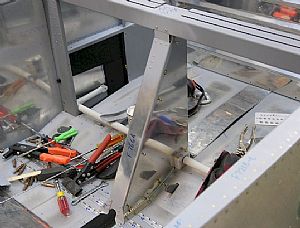

Drilled the holes into the F-766B bracket Drilled the holes into the F-766B bracket

I clamped the F-766B bracket to the channel and drilled it, using the holes in the channel as a guide.

|

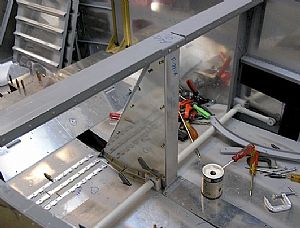

Tie wired the flap motor rod to the lower eye bolt Tie wired the flap motor rod to the lower eye bolt

Here's where I deviated from the plans (again). I tried to tie wire the flap motor rod to the bolt as stated in the instructions. But, when I played with moving the rod up and down by running the motor, the wire bent back and forth. I knew that after only a few sessions of applying the flaps, the wire would eventually break. So, in a previous building session, I drilled a small hole into the eye bolt (or whatever the hell this part is called). Then I tie wired the flap motor rod to the eye bolt. This solved the wire movement issue.

|

Started work on the F-785 backrest brace Started work on the F-785 backrest brace

I drilled the top two holes in the F-785 backrest brace using the predrilled holes. Then I installed the nutplates and screwed the F-785 backrest brace into place.

|

TIme to fit the F-760 Flap Actuator Covers TIme to fit the F-760 Flap Actuator Covers

The F-760 Flap Actuator Cover has to have a notch cut out to allow for the bolt that holds the flap motor in place. I decided to wrap some old sandpaper around a drill bit, taping it in place using scotch tape on top and bottom. Then I just moved the cover up and down on the drill bit until I got the depth of the cutout just right.

|

It woiked! It woiked!

|

Put the F-760 Flap Actuator Covers on Put the F-760 Flap Actuator Covers on

Now it's time to drill the holes into the F-785 backrest brace (to install the nutplates), using the flap cover holes as a drill guide.

|

Done! Done!

I only screwed the side panels on partially, knowing that they will need to come off later for running wires.

|

Home Previous Entry Next Entry Back

|