RV-9A: Ailerons - 6/2/2007

Home Previous Entry Next Entry Back |

Share on:

|

|

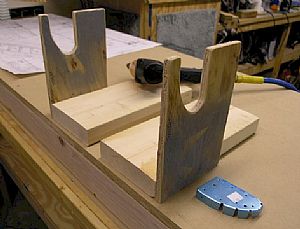

Built the particle board work top and the saddle jigs Built the particle board work top and the saddle jigs

This instructions say to build this work top from 1 inch particle board. All I could find was 3/4 inch particle board from Home Depot. At this point, I'm not sure that I even need to build this work top. I don't know why you couldn't just lay a piece of the particle board on top of a work bench, as long as the work bench is flat and level. But I determined to follow the instructions, since I don't know what to expect while building these flaps and ailerons. This work top consists of 1 4'x8' sheet of particle board, which is cut into 2 2'x8' smaller sheets. These sheets are then screwed to a 2"x4" frame on top and bottom, making this table top extremely flat and very heavy. Next, I built the saddle jigs, which were pretty easy to build. I decided to use 2x6 bases with extended bottoms to help offset the weight of the flaps and ailerons that will be hanging on the opposite side.

UPDATE: 8/17/2007 Now I know why Van's suggested building this temporary table top. You drill big holes in it when you start the flaps! I really need to read ahead.

|

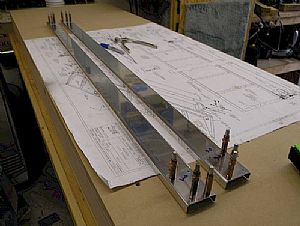

Clecoed the A-908 reinforcing plates to the A-903 spars Clecoed the A-908 reinforcing plates to the A-903 spars

I will start drilling these dudes tomorrow.

|

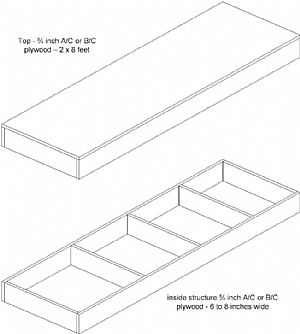

UPDATE: 12/08/2007 - That %^&* 2' x 8' work top UPDATE: 12/08/2007 - That %^&* 2' x 8' work top

On my next RV (arr-arr) I will do this table top a lot different. The work top I built has been total headache, for several reasons. The particle board "gives in" to the shape of whatever it is screwed to, namely the 2x4s.

It's nearly impossible to get straight 2x4's, and since they are probably "fresh from the tree", they will undoubtly warp over time. I found my self shimming all over the place to keep the table top level. If I had to start over, I would get some nice A/C or B/C 3/4 inch plywood for a top sheet. Then I would rip some more 3/4 inch plywood for the inner structure instead of the 2x4s. I would make the inner structure 6-8 inches wide. Then you shouldn't need the bottom sheet, since the larger and wider inner structure will keep the top sheet level and flat. Since plywood is mult-layered, it doesn't tend to warp as badly as the 2x4s. The idea here is you will be basically building a box. You will definitely still need the flat surface, unfortunately.

|

Home Previous Entry Next Entry Back

|

SmittysRV.com is an Amazon Associate

|