RV-9A: Rod's and ends - 1/11/2008

Home Previous Entry Next Entry Back |

Share on:

|

|

Got the Aileron Pushrods welded! Got the Aileron Pushrods welded!

I went to a local shop were they build custom choppers to get my aileron pushrods welded. I figured these guys must be into finesse. Lonnie, at Denton County Choppers in Frisco, TX, did a fantastic job on these puppies. He told me that he scotchbrited everything down, did the welds, and even primed everything after he finished, making sure not to get any primer on the screw ends. Very nice!

|

Now back to the large pushrods Now back to the large pushrods

I know I'm going to need a drill press jig to hold the pushrods so they won't turn during drilling. I got a scrap piece of 3/4" plywood and cut it down the middle using my band saw, set at a 45 degree angle

|

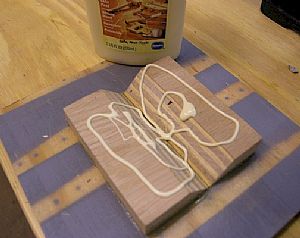

Glue time! Glue time!

I used Elmers wood glue to attach the plywood 2 halves to another piece of 1/2" plywood.

|

Poof!! (24 hours has just passed) Poof!! (24 hours has just passed)

Amazing what the internet can do. I want to make sure that the pipe doesn't move around while in the jig, so I decided to get some of the rubber stuff you put under throw rugs that keep you slipping and landing on your buttocks, and glued it to the "V" in the jig.

|

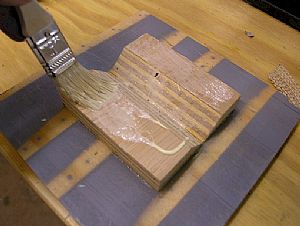

Spread the glue out Spread the glue out

|

Slapped on the rubber matting Slapped on the rubber matting

This stuff will help hold the big pushrods in place while I'm drilling. I laid another piece of plywood on top of the rubber matting to hold it while the glue sets up.

|

Home Previous Entry Next Entry Back

|