RV-9A: Canopy - 8/12/2012

Home Previous Entry Next Entry Back |

Share on:

|

|

Time to fit the WD-643-SS Canopy Brace Time to fit the WD-643-SS Canopy Brace

I say "fit" because the canopy brace will receive it's final tightening in place when the forward top skin is riveted on. This was a little bit of head scratcher. After looking at the plans, I determined that the deciding factor in fitting this brace would be the forward most bolt and the gap left for the top skin to go under the brace. I cut and clamped a couple of scrap pieces of aluminum that together would establish the gap needed for the top skin to go under the brace. The gap is a little larger than the actual thickness of the top skin. I drew a line on the flat flange of the brace 3/8 of an inch from the forward edge of the brace flange. This line would show up in the predrilled hole in the aluminum angle previously installed on the panel rib. All I had to do then was "eye-ball" the cut-off mark on the other end of the brace by laying it down on top of the roll-bar.

|

Cut off the end of the WS-643-SS brace Cut off the end of the WS-643-SS brace

I bought a new 34 tooth x 12 inch hack saw blade and cut off the end of the brace according to my eye-ball measurement. I purposely left it about a 32nd long so I could do a custom fit by test fitting it in it's final position and going back and forth to the old grinder.

|

Drill the holes into the forward flange of the brace Drill the holes into the forward flange of the brace

After getting a good fit on the aft end of the brace on the Roll Bar, I clamped the forward end of the brace in place and drilled the holes using the pre-existing holes in the support angle. Then I temporarily put the bolts in (not tight) to hold the brace in place so I could drill the large in the aft end of the brace on the roll bar.

|

Drilled the hole into the aft end of the brace Drilled the hole into the aft end of the brace

I started off by marking the place for the bolt hole a half inch from the forward edge of the roll bar attachent flange. I drilled a small hole on each side of the roll bar flange into the brace pipe using a 3/32 bit in my pneumatic angle drill. Then was easy to enlarge the hole to 1/4 inch using the 3/32 inch as a guide.

|

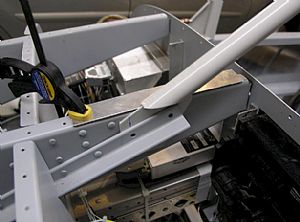

Thar' tis, as my dear old Dad would say. Thar' tis, as my dear old Dad would say.

Like I said before, I left the bolts loose, since this dude will have to come out for riveting on the forward skin.

|

What the heck, one more shot... What the heck, one more shot...

|

Home Previous Entry Next Entry Back

|