|

Share on:

|

|

|

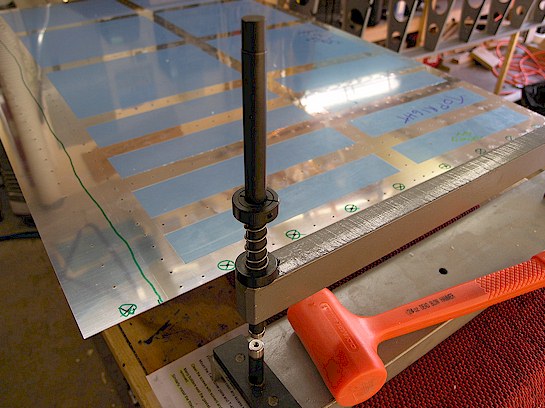

Started work on the smaller top inner wing skin

No pop-rivet dimpler for this dude. It’s pretty thick. Before I start dimpling any sheetmetal, I always find a small sheet from the sample bundle that came with the tail kit that is the same thickness as the one I’m about to dimple. Then I experiment using the pop-rivet dimpler against the C-Frame dimpler. In this case, the C-Frame dimpler won out, the pop-rivet dimpler couldn’t handle the thickness as was making dips in the practice piece. Tomorrow I will dimple this sheet with the C-Frame, giving each rivet hole one solid “WHACK” with my dead-blow hammer. I found that anything more than one solid whack tends to make a dip in the skin (for me anyway).

|

|