RV-9A: Left Fuel Tank - 7/3/2006

Home Previous Entry Next Entry Back |

Share on:

|

|

Started getting the left tank skin ready for pro-sealing the ribs in Started getting the left tank skin ready for pro-sealing the ribs in

I put 3M Painters tape around where the ribs will go. Boy, this tape really has a strong odor to it, when you pull a lot of it off the roll.

|

Time to put all the ribs back into place (my favorite part) Time to put all the ribs back into place (my favorite part)

I started by putting in 2 clecos in the bottom 2 holes on one side of the ribs.

|

Did the same on the opposite side Did the same on the opposite side

I used some duct tape to pull the skin together just enough to get 2 clecos in the bottom holes on the opposite side of the ribs. Did you know that Lowes and Home Depot sell 3 different types of duct tape from the same company? One is a professional grade tape, one is a "wanna-be" grade tape and the other is just pure crap. In fact, when I ask my kiddo to throw me some duct tape, he asks "Which one ya' want? The good tape or the crap tape?"

|

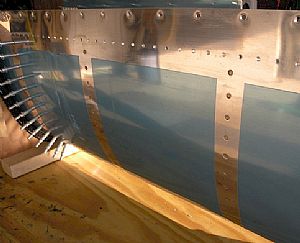

Slipped the tank skin into cradles Slipped the tank skin into cradles

It's easy now to put the rest of the clecos. I started at the bottom and worked my way up. The tank sunk slowly into the cradle as I put in the clecos.

|

Started putting in the ribs Started putting in the ribs

I didn't take many pictures of this process, mainly because I was covered in black goo (proseal) and didn't want to get any of it on my camera. I managed to put in 3 ribs, over a 3 day period, one each day. In this hot weather, the proseal sets up in 45 minutes, so I had to work fast on each one. The first rib was a real "ah-ha" experience of how not to do it. When I finished the first rib, there was proseal everywhere inside the tank on the skin. I really should have gotten a helper to buck the rivets. The first rivets on the top leading edge were almost impossible to rivet and buck by myself, the rest were pretty easy. On the other 2 ribs I got some typing paper and taped it inside the skin to prevent the proseal from getting on it. The rib in this picture is the second rib I put in. I ain't gonna show ya' the first one. When you pull off the painters tape, you get a nice straight line of proseal to impress your friends. They will think that you know what you're doing.

|

Here's the other side of the good rib Here's the other side of the good rib

Laquer thinner really works good to get the proseal off, but you really have to rub. If you get the black goo on your hands, you can get most of off, but you won't be able to get it off completely. It likes to stay put in your old fart wrinkles. One other note. I was really surpised at how easily the ribs came out and back in (one at a time) when applying the proseal to the edges of the ribs. You would think that it would difficult to do, after the rigorous process of clecoing all of the ribs inside the tank skin. After applying the proseal to the edge of a rib and putting it place, I put one cleco in the third hole from the leading edge on each side to initially hold the rib in place. Then it was easy to put the rest of the clecos before starting the riveting process. I found that it takes about 22 cc's of mixed proseal for each rib.

|

Here's a shot of the rivet heads on the top of the tank Here's a shot of the rivet heads on the top of the tank

The proseal comes out around the heads of the rivets as your rivet them. When I cleaned them up with the Laquer thinner and a paper towel, I left some of the proseal showing around the edges of the rivet heads. Can't hurt.

|

Saving your skin Saving your skin

The aft edge of the fuel tank skin is really hard on your arm when bucking the forward most rivets on the first rib. I found this soft rubber hose (1/4 inch thick) in my garage and decided to make an edge cover out of it. I cut a slit in it and put on the edge of the tank skin.

|

Here's a shot of the foam rubber hose on the tank skin Here's a shot of the foam rubber hose on the tank skin

This was a lot better, a nice cush for resting my arm while riveting.

|

Tried it out on the wing ribs Tried it out on the wing ribs

Yep, that'll work. I seen pictures on other builders web sites where their arms were all red from reaching in through the lightning holes to buck rivets and install stuff. This soft foam rubber hose is the kind of hose that goes over air conditioning pipes, not the pre-split hose for outside water pipes. The pre-split water pipe insulation is too stiff for this type of application.

|

Home Previous Entry Next Entry Back

|